|

Church of Santiago Apostol, central Tequila, Jalisco,

Mexico

Less

than 2 hours by bus from Jalisco's capital city of

Guadalajara, today, the city of Tequila is a World Heritage Site.

Legends and myths envelop the distilled drink of the

same name, and to appreciate the finesse and the fire of

tequila, one must reach deep into the core of Mexico to

learn more.

The

Blue Agave, agave tequilana weber azul

Archeologists say that agave has been cultivated for at

least 9,000 years. Legend has it that centuries ago,

a lightning storm caused a fire in the native agave

fields. Plants exposed to the heat of this fire were roasted and split

open. Sweet juices oozed from these cooked and

burst succulents and the indigenous people found them to

be agreeable to their taste. The plant had already been

used to make rope, thread for clothing, with the prickly

points being fashioned into a

sort of nail for construction or used as a needle to sew.

Now

they had food, and surprisingly, a sweet drink called

agua miel or honey water.

Aztecs enjoying pulque

The

local indigenous people considered this sweet drink from

the agave to be a gift from the gods. After all, it was

discovered after powerful light from the heavens struck the earth causing

the juices to flow. Later they learned

to make a kind of beer from the fermented agua miel,

and that drink was called pulque.

Stone

archways reflect the architecture of the Spanish

Conquistadores

Tequila is North America's first distilled drink and its

first commercially produced alcohol.

When the

Conquistadores came, they made distilled 'tequila wine'

from the pulque drink of the Aztecs. Don Pedo Sanches de Tagle established the very first tequila

factory at his hacienda in 1600. One hundred-sixty-five

years later, the Spanish

government wanted to favor the importation of Spanish

wines and spirits to the New World, so consequently the

Crown banned all

locally made spirits including this mezcal wine.

Legally, production was halted, but of course the trade

simply went underground.

King

Ferdinand IV lifted the ban in 1792, but it wasn't until

after the Mexican Revolution from the Spanish in the

1800's that

tequila regained its prominence.

The

Jose Cuervo distillery complex in Tequila

The

first licensed manufacturer was Jose Antonio Cuervo who

received special rights in the mid 1700's from the King of Spain to

cultivate a plot of land in New Spain. His son, Jose Maria Cuervo, obtained the first license to produce mezcal

wine and founded Casa Cuervo, the first official

Mexican distillery in 1795.

In

1812 when Jose died, his son-in-law, Vincente Albino

Rojas, changed the name of the Casa and increased

production. By the middle of that century, the family

rancho holdings had more than 3 million agave plants.

Today, the largest manufacturer of tequila is Jose

Cuervo, and their export market is huge.

The

National Museum of Tequila is a must see.

Big

museum, easy to find

Located on

Corona #34, this national museum presents the history of the

making of tequila. Providing good photographic exhibits,

a large collection of bottles from the many distinct

styles of the local distilleries, there are explanations

of the mechanics and history of tequila, as well as good

displays of the local culture.

There is a

tequila tasting in the gift shop at the end of your self-guided tour. Certainly worth the 15 Peso admission

fee, and we recommend that you visit!

Big

museum, easy to find

Each

of these individual rooms house displays of the history

of tequila, the first distillers, photographs of the

fields, the jimadores or harvesters working, collector

bottles, antique displays of tools of the trade, live

Blue Agave plants and more.

The

first thing to greet you is this stainless steel still

with the Virgen de Guadalupe etched boldly on the

center front. Mexicans are still asking those of heavenly

patronage

to bless this beverage. On the top sides, Blue Agave

plants are etched in as well.

Mule

driven cart

The

cart above is an antique. In years past, these carts

would be loaded up with harvested pinas and brought to

the distilleries by mules, oxen or horses. Carts are

still used in fields today, if the terrain is such that

trucks cannot reach the plants.

Blue

Agave pinas after being harvested from the field

When

the spines are hacked away, the

center of the agave plant looks much like a pineapple - hence the word,

pina. In olden days, these pinas would be slow roasted in

a brick or adobe oven for 24 to 36 hours to process the

natural juices and soften the fibers.

The

consistent, slow cooking temperature of about 150*F keep the agave

from caramelizing which would add a darker color and

bitter flavor.

Only three or four more rotations

and Billy will have this down!

After

the pinas cooled for another 24 to 36 hours, they were

crushed by a stone wheel such as the one pictured above.

These stone wheels were driven by mules, oxen or horses

until the fibers were pulverized and in shreds. These

stone wheels, called tahonas, could weigh up to 3 tons.

If you look really hard you can

see the chair she is sitting on. If you cannot see it

perhaps you need more tequila!

There

is a distinct tequila art culture displaying the

effects, the joy and the history surrounding the beverage.

This art culture is heartily embraced by the locals complete with

awards given.

The

Sauza distillery named La Preservancia

Sauza

is another historic name in the tequila industry. In

1873, Don Cenobio Sauza bought his first distillery and

started making mezcal wine. Some say he was the first to

determine that the Blue Agave was the best maguey with

which to make tequila, and the other distillers followed

his lead.

Sauza

was the first to export tequila to the USA when, in

1873, he sold three barrels to El Paso del Norte, The

Passage to the North, or what we

know as El Paso, Texas today.

These days, Sauza owns around 300 plantations of agave and is

the second largest manufacturer of tequila.

Our tour guide at Sauza distillery, Karina Sanchez

Huitron

We arranged for

a private tour of the Sauza distillery, and Karina was

our guide. Behind her you will see a commissioned oil

painting that depicts the history and stages of

production in which tequila was made centuries ago.

After being cooked in ovens, and crushed by the

tahona, what was left of the pina was transported to fermentation

tanks. The resulting juices were distilled to make

tequila.

If you look

closely at the fermentation tanks in the painting above, you will see one

worker transporting the crushed agave into the tank, and

another worker in the tank itself. Centuries ago,

fermentation was done through bacteria, and the manner

in which this bacteria was introduced into the vats was

by having workers come in from a day in the fields and

stand in the juices. The bacteria from their bodies mixed

with the agave sugars and began the distilling process.

Sauza

distillation tanks today

Of

course, today, yeast is used for the fermentation

process, and emphasis is placed on sanitation of the

product and worker safety.

Sauza

has a distinct manner in which it processes its tequila,

different from the methods of ages past. Instead of

roasting the pinas in an oven to release the sugars of

the agave thereby giving a smoky taste to the resulting liquid,

Sauza decided to keep the unique flavor of the agave

plant itself. At this stage, the Sauza distillery shred

their pinas and through steam and hot water, juices and

sugars from the pinas are released. This

non-roasting approach is

considered a high volume method of production.

Entranceway out of the distillery and to the original

home of the Sauza family

Quinta Sauza was built in 1836. Today, it is protected

by World Heritage restrictions, where nothing is to be

modified. It reflects the home as it originally was

years ago.

Running fountain in Quinta Sauza

There

is a curious historical fact about this home. The last

woman to live here had no children to whom she could

will her estate.

Approaching the Cuervo family, she offered to sell her

property to them, but was rebuffed. Apparently the rival

tequila family thought the Sauza holdings could be

purchased cheaply at auction since there were no direct

inheritors.

The

business plan backfired, and the home and gardens were willed to

the servants.

Today, this prized piece of land sits in the Center of

the Cuervo landholdings. The Cuervo family is the number

one tequila manufacturing distillery in Mexico. Sauza,

producing 23 million liters per year is the number two.

Gonza,

the barrel maker

Tradionally, tequila was kept and transported in

barrels. In the late 19th century, Cuervo was the first distillery to put tequila

into bottles, but the barrel maker is still very much in

demand even today.

All

tequila is clear right after distillation and any

subsequent color is derived from aging in wooden barrels

or from additives.

Gonza

shows his imported French, Canadian or American barrels

Reposado or anejo tequila is aged in white

oak barrels stored in warehouses. This aging

process smoothes out the fire of tequila and imparts a

golden color.

Gonza's son cutting wooden pieces from used barrels

Used

white oak barrels from North America or France are

broken down, sanded and cut into smaller strips.

A

closer look at hand cut wooden pieces for smaller

barrels

Since

these barrels have previously stored wine or other

spirits, they have already been cured. Gonzo sanded and

chipped away at a sample piece of wood, and the scent

coming from the wood was very aromatic.

Nothing is wasted

In

order for the narrow pieces of wood to bend properly

into the barrel shape, the inside of each strip is chipped

away at its center making the wood easier to form a

curve.

A

quick hammering and steel bindings

Wooden strips are fit into steel circular forms and

pounded into a tight fit.

Barrel strips softening in hot water

The

next step is to place the barrel into hot water to

soften the strips so they can be bent into a round shape

more easily.

Notice the fire under the steel drum filled with water.

Squeeeeze!

After

the partly finished wooden barrel has been soaked and

softened, steel cables are wrapped around it. The steel

cables are tightened and the remaining end of the barrel

becomes narrower so that the last steel form around the

barrel can be put into place.

Wood

chips smoke the insides

The

lip of the barrel completes the form. Then the dried

barrel receives another touch: burning wood

chips. This will add color and flavor to the stored

tequila.

Gonzo

burns a design into the barrel top

Barrels are made into popular 1 liter, 2 liter and 5

liter sizes. Larger barrels for distilleries are made as

well. Designs are burned into the wood by hand.

Barrels almost ready for us

A

hole is drilled into the center of the barrel to fill,

where the tequila will be 'rested' (reposado)

or aged (anejo).

Gonzo's barrel factory

Gonzo

and his family have been proudly making barrels for five

generations. He told us that he also makes these large

barrels (pictured above) for the local tequila

distilleries in the area and he has a thriving business.

An

example of one famous distillery using these white oak

barrels

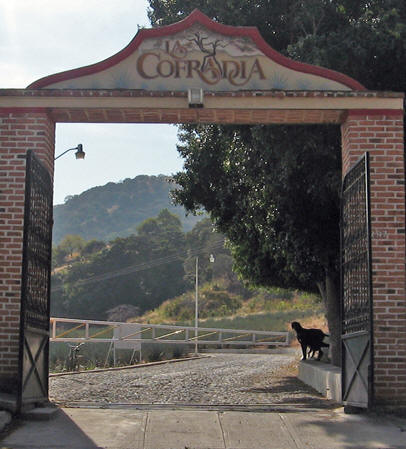

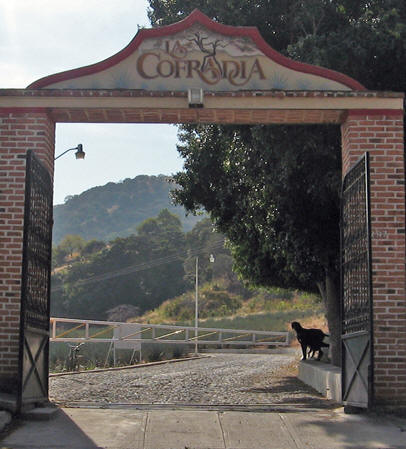

Stunning surroundings of Cofradia distillery

Founded just over fifty years ago, Cofradia is a newcomer

to the world of tequila and is now the 7th largest exporter

of this distilled beverage. The name 'Cofradia' means

brotherhood.

Don

Carlos Hernandez, the founder of Cofradia

Blue

Agave pinas being harvested in the fields

In

order to be labeled 'tequila' there are certain

requirements to be filled according to Mexican law. The

key distinguishing identity is that it be made from 100%

agave. Some bottles will put 100% agave azul,

which means it is made from agave tequilana weber azul.

In order to be sold as tequila, it must be made only

from this particular succulent, approved by government

inspectors to insure purity, and be bottled in Mexico.

If

the bottle is not labeled 100% agave, they are

considered 'mixtos'. Up to 49% of the alcohol can be

made from other sugars such as cane sugar. They have

less taste than the agave sugars, and caramel and almond

essence can be added for both color and flavor.

Mixtos are generally used for Margaritas and other mixed

drinks. They are not sipped straight since their flavor

is not prized.

Closer view of harvested pina

The

agave tequilana weber azul has a lifespan of 8-14

years, depending on soil, climate and cultivation

methods. It grows in developed fields on high plateaus

in mineral-rich red soil and volcanic earth. There can

be 1,000 to 2,000 agaves growing per acre.

The

Blue Agave takes from 8 to 12 years to reach the stage

where the sugars are suitable for fermentation. The more

mature the plant is, the better its natural sugars.

Jimadore working in the field

Today, most fields are still hand cultivated.

Traditional methods are passed down from generation to

generation and some fields have three generations of

harvesters working them.

Notice the shin guard that this Jimadore is

wearing. Perhaps experience has taught him something.

Those tools are razor sharp.

Gets

paid by the pina

This

harvester was a bit shy but it's possible that he didn't

want to be disturbed in his production. He told us that,

depending on the size of the plant, he could harvest

100- 200 pinas in a day.

A

mature pina can weigh from 80 to more than 300 pounds.

A

closer look

The

Jimadore slicing tool cut through the succulent

stalks like a knife though softened butter. We had never

seen anything like it. There was no hacking, no jerking

motion, no repeats; just smooth swings one after

another which removed the blue-green pencas.

Finishing one row, beginning another

It

can be a long day in the fields. Row after row is

harvested and the Jimadore is paid by the pina.

Fields are not irrigated. The agave plants depend

entirely on the rainy season for their moisture.

Irrigation experiments were tried, but the larger plants

did not result in producing more agave sugars, so the

technique was abandoned.

Individual coas are kept razor sharp

When

left to grow in the wild, mature agave plants produce a

tall stalk with a flower on the end. These flowers are

pollinated by long nosed bats to produce seeds so the

plant can reproduce. As long as the shoot is growing,

all the nutrients and life of the pina is being

used up to support the flower.

In

other words, as the stalk and flower live, the pina

dies.

This

is why the stalks on the agave plants in the orchards

are cut before they take the nutrients from the heart,

and the hearts are harvested at that time.

Blue

Agave shoots

Another method of reproduction of this succulent are the

shoots that the plant sends out when they are between 4

to 6 years old. When the shoots are about the size of a

leek, they are transplanted, and the agave fields are

replenished.

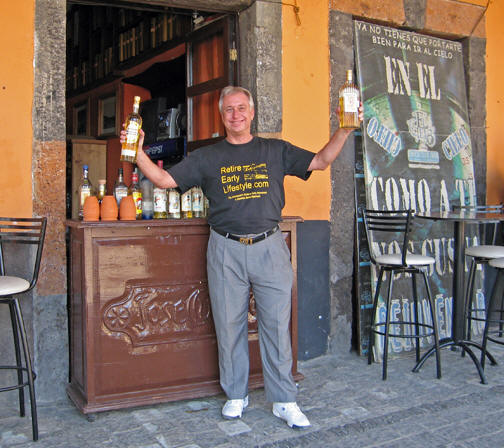

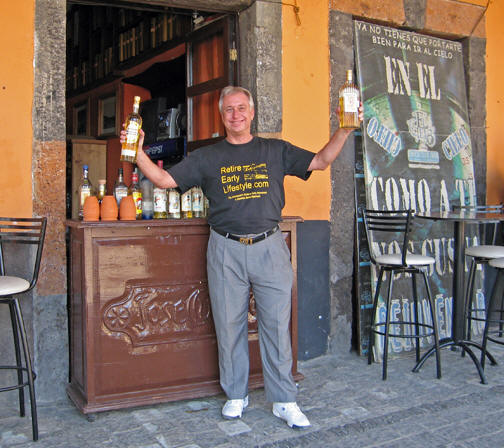

Billy

tries his hand at pina harvesting - picking up

some extra cash in retirement

When

the plant is ready for harvesting, the carbohydrate-rich

heart is cut from its roots. The

Blue agave must be replaced with new shoots and the

cycle begins again. In another 8-12 years that next crop

will be mature.

\ \

Blue

Agave fields

Since

it takes so many years to harvest the pinas for

tequila-making, alternate crops like corn and beans are

often planted in between the rows of agave plants. This

helps to rejuvenate the soil as well as bring in backup

income from the fields.

Tools

of the trade

The

harvesting of the agave plant is still done by hand. In

this manner, the size of the pina is controlled

which is necessary to facilitate its consistent cooking

in the ovens. Pinas of differing sizes

cause some plants to be overcooked while others are are

under cooked.

Our

guide, Alejandro, demonstrates the pina size that

is preferable.

This series of machines shreds and

crushes the pina after cooking

After

the pina is harvested, it is brought to the

distillery, baked, then crushed, shred and drained of its

juices. This modern machine is a bit like a wood

chipper.

Five

generations in the tequila business

Vincente Orendain acquired a distillery from Jose

Antonio Cuervo in the 1830's. Through the generations,

the Orendain family has bought and sold their factories

and modernized them.

Tequila Orendain is the third largest exporter of

mixto tequila.

El

Lano is a boutique distillery that sells several brands

of tequilas, including 100% agave azul.

An

inside look

This

is the distillery and the tanks are modern stainless

steel.

Our

guide at El Llano proudly explains the distilling

process

Different bottles, different styles of tequila, same

distillery

Each

distillery that we visited made numerous

labels to sell their product, some with as much as 80%

of their tequilas being

exported.

There

are blancos and platas, mixtos, reposados and

anjeos. Each style appeals to a different type of

customer and their preferred taste.

Different brands, different flavors

A

symbol of Mexican national pride, the production of

tequila is now a thriving business, with most tequila

being exported around the world. There are 911 different

domestic brands of tequila, plus 158 labels used for

export only.

How

do you know what kind of tequila to buy?

Stay

tuned for

Part III, The Taste of Tequila!

If

you want to know more about the city of Tequila, Jalisco,

Mexico,

click here

For

more stories about places of interest in Mexico,

click here |

\

\